One of the least considered aspects of any type of wire form manufacturing is the packaging.

Our customers put a lot of time and energy into designing a part, material consideration, and finding the right shop to do manufacturing. However, the one thing that all parts inevitably have in common is the packaging. After all the design and manufacturing are done parts have to be packaged before they can be shipped.

The Importance of Packaging

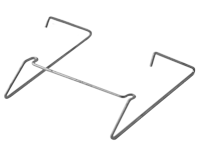

One of the most important services we offer is the packaging. This might come as a surprise since customers almost never consider packaging at the start of the design or manufacturing process. However, wire forms themselves, whatever their end-use, tend to (by nature) feature many different bends, coils, and variations in shape. Packaging may not seem like an important consideration, but when hundreds or thousands of individual units are poorly packaged they very easily become tangled, forming hard to separate knots of parts.

During shipping, even simple parts can become hopelessly tangled and balled up as the package is moved, shook, and jostled. This can mean costly manual detangling and sorting once the parts have reached their destination. When you consider the volume of parts, the time that has to be spent sorting and detangling can become significant very quickly.

This is why we work with customers to create packaging solutions that minimize balling and tangling. A custom packaging solution is not always the most cost-effective. However, for complex parts with many bends and coils, it can often represent a significant benefit in terms of time and cost to create a packaging solution that minimizes these problems.

Common Packaging Solutions

Sometimes packaging solutions are as simple as using more bags for the same number of parts. For example, rather than 2,500 pieces per bag, 500 pieces per bag can make a big difference in tangling.

Another common packaging solution is rubber banding parts, or groups of parts, as they come out of the machine.

Scatter packing, however, is by far our most common packaging solution. Typically, we will scatter parts over the sticky paper to keep them from tangling. This is more cost-effective than manually sticking each part to sticky paper, but greatly improves the overall packaging of the parts.

The Importance of Planning Ahead

We have a lot of experience packaging parts and the most important thing you can do to keep packaging costs down is discuss them upfront. If you put off packaging considerations until after production it can significantly impact the overall cost of the product. However, because we have so much experience with packaging we can often find a packaging solution up-front that saves everyone time and money.

Our wealth of experience packaging all types of parts means we can often work a packaging solution into the production process that helps minimize tangling and is cost-effective. Waiting until production has begun or is finished, however, can make packaging more difficult.

Getting You From Design to Shipping

We have extensive experience in all aspects of wire form manufacturing. We can help you go from the designing phase all the way through shipping using our experience to create an ideal solution that’s cost-effective.

Contact us about your wire form needs or to learn more about our design, manufacturing, and packaging services.